Restaurants, hotels, hospitals, and other establishments that generate significant amounts of fats, oils, and grease (FOG) produce wastewater that can cause clogs and sewer backups. These problems can be costly and result in fines from the municipality.

Grease traps protect these establishments’ plumbing systems by collecting FOG waste before it enters the sewage system. To function properly, a trap must be cleaned/pumped out regularly. Contact Grease Trap Perth now!

When wastewater flows from restaurant kitchen drains, it’s laden with fats, oils, and grease (FOG). Because sewer collection systems are designed to take wastewater to sewage treatment plants, FOG can clog pipes and lead to sanitary sewer overflows. To prevent this, many cities require locations that prepare food items to install grease traps (also called grease interceptors) and maintain them regularly.

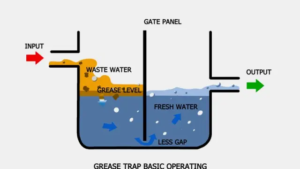

Grease traps (and interceptors) work by slowing down the rate of wastewater so it has time to cool and separate into 3 layers. Since animal fats and vegetable oils are less dense than water, they rise to the top of the receptacle while solids settle to the bottom. The separated clear wastewater exits through an outlet pipe.

Depending on the size of your establishment, it may be necessary to install more than one grease trap. Typically located outside, they range in size from small units that connect individual sinks to large-scale installations for entire facilities. Your location, production volume and available space will help determine the type of installation you need.

Most traps contain a baffle wall that keeps the different levels of wastewater from mixing. This keeps the fats, oils and grease at the top of the trap from escaping into the main sewer system. Wastewater then passes through the receptacle and into the treatment plant.

A well-maintained grease trap will prevent sewer backups and keep your kitchen running smoothly. The frequency with which you must clean and/or pump your grease trap will depend on how often your business is busy and the amount of grease that’s washed down the drains.

You can avoid expensive repairs by having your grease trap cleaned before it gets full. A standard plumbing industry rule is that a trap should be cleaned before it becomes three-fourths full of FOG materials. Depending on the size of your trap and the kitchen practice, this may mean that it must be pumped at least every two or three weeks. Alternatively, a biological grease treatment fluid can be added to the trap that combines non-pathogenic bacteria and nutrients to break down FOGs and prolong grease trap performance.

Grease Trap Installation

Grease traps intercept fats, oils, and grease (FOG) from wastewater before it enters the sewage system, preventing blockages in kitchen drains and environmental contamination. They are essential components of commercial kitchens and restaurants, and proper installation and maintenance are important for their efficient operation and compliance with local regulations.

There are several steps involved in the installation process, including securing any necessary permits and ensuring that the site is suitable for the size of the grease trap chosen. The area should be free of debris, level, and well-drained to prevent any buildup or spillage. If the grease trap is being installed outside, it will also need to be properly insulated and sealed to prevent cold temperatures from damaging the unit.

Once the installation is complete, the grease trap should be tested to ensure that it is working properly. The best way to test a grease trap is by pouring boiling water down the drain, which will cause the grease in the trap to rise to the surface and be removed from the wastewater system. This process will also show if the sizing of the grease trap is appropriate for the business.

In order to prevent future problems with the grease trap, businesses should have it regularly cleaned and inspected by a professional service provider. If a grease trap is not maintained regularly, it can overflow and create a mess in the kitchen and throughout the entire building. In addition, improperly installed or malfunctioning grease traps can cause damage to sewer lines and lead to costly repairs.

The cost of installing and maintaining a grease trap varies depending on the size and type of unit chosen, as well as any permit fees or inspection costs that may be required. Regardless of the price tag, businesses should be prepared to invest in a grease trap that will provide long-term benefits and save them money in maintenance and repair costs in the future.

Grease Trap Maintenance

Grease traps are essential for reducing the amount of fats, oils, and grease (FOG) that enters sewer lines. They work by filtering kitchen wastewater to separate the FOG from the rest of the waste so it can be disposed of properly. However, like any kitchen equipment, they need to be properly maintained or else they can fail causing costly clogs and noxious smells.

There are a few different ways to maintain a grease trap, but the most important is regular cleaning. It is recommended that restaurants, schools, and other commercial kitchens have their grease trap cleaned by a professional at least every eight to 12 weeks. A professional service will clean the trap to prevent odors, back-ups, and ensure it is working effectively.

To clean the grease trap, start by running cool water through it. This will help to congeal the grease, making it easier to remove. Next, carefully remove the grease trap lid. This may require a wrench, crowbar, or other tool, depending on the type of grease trap. Once the trap is uncovered, use a tape measure to determine how full it is of FOG materials. If the trap is more than a quarter full, it should be cleaned as soon as possible to avoid grease leaks and overflows.

When cleaning the trap, be sure to wear rubber gloves, safety goggles, and a face mask. This will protect you from the toxic hydrogen sulfur gas that is created during the decomposition of the FOG material in the trap. Once the FOG has been removed, a bucket and scoop can be used to remove any solids that have accumulated on the bottom of the trap. These should be removed and placed in a water-tight garbage bag for disposal.

It is also a good idea to use strainers on sink drains to catch food waste and debris. Additionally, educating employees on proper food preparation and disposal practices can help reduce the amount of grease that ends up in the trap. FOG that is not disposed of properly can also cause wastewater systems to backup, leading to sewage overflows and expensive repairs.

Grease Trap Replacement

As with anything in the restaurant business, the up-front costs of installing and maintaining a grease trap can be daunting. But the overall savings that come from using a grease trap far outweigh the initial investment.

A grease trap is a vital tool in any commercial kitchen, helping to prevent sewer system backups and protect your establishment’s reputation. But a grease trap isn’t a magic bullet, and it requires regular maintenance and cleaning to keep it functioning properly. A well-maintained grease trap can help you avoid expensive and time-consuming repairs or replacements, while also ensuring compliance with city Fats, Oils, and Grease (FOG) regulations.

The cost of a grease trap depends on its size and how frequently it needs to be emptied. The best way to determine which grease trap is right for your establishment is to talk to a licensed professional who understands the intricacies of your kitchen’s plumbing system and local FOG ordinance requirements.

Typically, a stainless steel grease trap is the best option for most restaurants. These durable units are rust-resistant and able to hold high volumes of grease without clogging or overflowing. If your budget doesn’t allow for an automatic unit, you can still enjoy the benefits of a quality grease trap by investing in one with a smaller capacity and lower up-front cost.

Aside from the initial purchase costs, you’ll also incur ongoing pumping fees and disposal costs when using a grease trap. It’s important to weigh these expenses against the up-front cost of different grease trap options to make an informed decision about which unit is best for your establishment.

During routine cleaning, it’s a good idea to wear a mask when opening the lid of a grease trap. The foul odors produced by decomposing grease are often quite strong, and they can spread throughout your entire building.

Another sign that it’s time to replace your grease trap is a visible build-up of solidified grease on the surface of the tank. This is a clear indication that the internal components of your grease trap are beginning to wear down, and it’s crucial to address this issue before it causes a major clog.